Tensile + Universal testing machines

HQ mechanical engineering with excellent testing software

Why are GALDABINI tensile / universal testing machines cheaper for the same quality?The only answer is: Because other manufacturers are too expensive in comparison. We use equivalent components in our machines (BECKHOFF electronics, BOSCH REXROTH spindles, brushless AC motors and digital motor controllers), which are also used by the established suppliers. Competitors, however, capitalise on the higher level of recognition and claim to be able to offer higher quality. We would be happy to convince you of the quality of our tensile testing machines and probably the best testing software in the world (?) - challenge us. |

Tensile testing machines and universal testing machines are basically identical machines. Additional equipment turns a universal testing machine into a tensile testing machine (clamping heads, extensometers), a compression testing machine (compression plates) or a flexure testing machine (3-point/4-point bending device).

As a rule, a tensile testing machine / universal testing machine can also be used for cyclic tests. In these tests, the specimen is mechanically aged until "fatigue". The component is subjected to repeated force or deformation loads. In most cases, a fatigue crack or fracture occurs after a high number of load cycles. A GALDABINI tensile testing machine / universal testing machine < 2.5 kN is offered in C-design as a table-top machine / > 5 - 100 kN in O-design as a table-top machine / > 200 - 2000 kN in O-design as a floor-standing machine.

Tensile Testing Machine

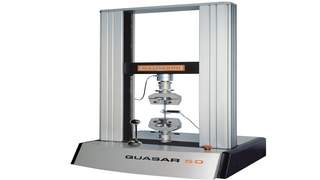

5-100kN Table Top Machines

Table Testing Machins QUASAR

- O-Frame 5 | 10 | 25 | 50 | 100 kN

- Forces 0,02 - 100.000N

Tensile Testing Machine

200-2000kN Floor Standing

Floor Standing Machines QUASAR

- O-Frame 200 | 250 | 600 | 1000 | 1200 | 2000kN

- Prüfkräfte 0,02N - 2 MN

Reasons to make Galdabini Testing Machines your first choice

The quality meets also high expectations and is equal to the market leaders it is now known in the market that equipment from GALDABINI are positioned in the top technical field and offer an excellent price-quality ratio. Through an enormous encouragement after the start up after only seven years in 2011 in German we are positioned as the no. 2 top brands (number / year of sold machines). Often competitors argue that they are able to supply superior quality. GALDABINI - testing machines are made in Italy using only finest European components: German Control electronic from BECKHOFF, German ball screw spindles from STAR, load cell class 0.5, PHÖNIX - electro components etc. Quality deserves this description - GALDABINI supports this with a 2 year warranty.

This quality / price level hardly provides a third-party

If the quality is confirmed (!) at least it is a question of price. So the leading position on the market is not only a question of quality but a question of fair prices.

This unbeatable customer value is able to grant because GALDABINI defined standardized design of the machine and building bigger batches of machines. Ask for a not binding offer and convince yourself as already hundreds of other customers have done (ThyssenKrupp, HILTI, MAGNA, Dr. SOMMER Werkstoffprüfung, TÜV Hamburg, TÜV Duisburg, ArcelorMittal

)

Engineering Universal and Tensile Testing Machines

Several manufacturers of testing machines should use the description "assembler". They are using foreign know how and building a testing machine collecting a load frame, foreign control electronic, foreign testing software, clamping heads, testing equipment. GALDABINI is convinced that the core competencies must remain in the company to ensure the smooth interaction in a testing machine. As one of the few manufacturers GALDABINI therefore manufactures its own extensometers (fully automatic extensometers, laser speckle extensometers, long stroke extensometers for plastics), own grips (hydraulic grips with integrated force proportional clamping pressure control, wedge grips, ...) and has its own production for all machine-structure parts ...

Spare parts and service for universal testing machines

As a leading manufacturer Galdabini grants the supply of all typical spare parts available from stock.

The service and calibration to your equipment takes place in almost all cases by the SCHÜTZ+LICHT Prüftechnik, but is supported by the manufacturer - in some cases, sometimes even at next day ...

The range of machines are covered by three different kind of frames

Single column frame QUASAR 2,5 in C-shape design (table top)

Double column frame QUASAR 5, 10, 25, 50, 100 kN (table top)

Double column frame QUASAR 200, 250, 600, 1000, 1200, 2000 kN (floor models)

GALDABINI frames are extremely solid: Thus far, not a single load frame damage known (!).