Sheet metal cupping test 2.0 BPM650: Quick testing deep drawing

<3 minutes: qualifying deep drawing capability of your material

Problem + solution - sheet metal testing 2.0

At manufacturing of deep drawing parts the required properties of deep drawing sheet metal material often are extreme: High / extraordinary elongation , good cold forming properites, uniform thinning, fine-grained to avoid cracking ...

If a sheet metal coil is fed into the production process without being checked, a not inconsiderable amount of damage can occur (if the quality is insufficient). If a material defect is only detected at the end of the process, not only is the set-up time lost but valuable production capacity is wasted. In addition, there is the complaint with the supplier, the disposal of defective parts and the new production (with hopefully suitable sheet metal ...).

This can be avoided by checking the sheet metal before production starts (ideally when the coil is still loaded on the delivery truck).

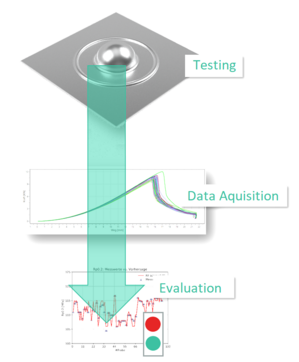

The FRAUNHOFER Institute IWU in Chemnitz has developed an intelligent quick test for this purpose. Based on the standardized ERICHSEN cupping test, a load cell and a high-resolution distance measuring system have been integrated into a specially developed tool. Using intelligent, self-learning evaluation software, it is possible to make a statement on the suitability of the sheet metal within a few minutes: Remove a piece of sheet metal using a flex / portable nibbler, place it in the deepening tool and start the test. Using the stored library, the FRAUNHOFER evaluation software determines the suitability of the sheet metal for your deep-drawing process within only about 3 minutes.

Sheet metal deep drawing (cupping) machine new invendet:

First presentation 4th expert conference punching at FRAUNHOFER Institut IWU - Chemnitz: 30.09.2020, 09:00 - 15:00 Uhr

click here to register

Research topic and project idea for sheet metal testing

Material testing 2.0

- The timely qualification of sheet metal batches for forming saves costs and production losses if the following questions can be clarified in advance:

- the delivery quality corresponds to the standard?

- the deep drawing process fails during forming / subsequent process steps

- Previous qualification: Determination of material properties via tensile tests

- Tensile sample production (punching and grinding)

- tensile test execution + evaluation

- ➨ conventional evaluation by tensile test is complex + expensive

- Nevertheless: it is often not possible to draw exact conclusions about formability on the basis of tensile tests

- elongation at break + tensile strength are determined from a single axis test

- R+N value determination does not always correlate with the deep drawing forming requirements

- the material characteristics are often only conditionally meaningful for e.g. drawn parts

How can a rational statement be made about ability?

How can a rational statement be made about the ability to deep drawing?

- Determination of pseudo material parameters

- the test is similar to the ERICHSEN cupping

- in the test a load condition suitable for forming is simulated

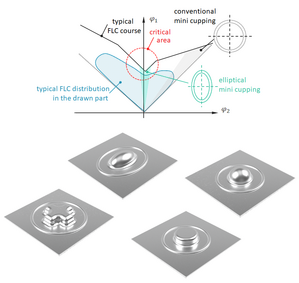

- Determination of the process-specific characteristic values through tool-integrated miniature experiments

- Prediction using ML-based methods (machine learning):

- Qualitative statement (tears / does not tear)

- in addition to ability of deep drawing there may also be quantitative parameters: Rp0.2, Rm, A...

- Fast incoming inspection / detection of scrap material

- Use also by semi-skilled employees (no materials test engineer required)

Miniature experiments allow a simulation tailored to your production conditions

- As offline device (first presentation at the 4th symposium on stamping and forming Chemnitz: 30.09.2020, 09:00 to 15:00 hrs

click here to register- Laboratory system with measuring tool and hydraulic press (mobile on request)

- from Mai 2020 available at IWU (demonstration)

- various test geometries according to your requirements are possible / design according to load condition required

- Future prospects: Integrated as an inline solution in your forming tool (Industry 4.0)

- Integrated in forming tool / on blank shear

- Test geometry in the waste area (drawing plant)

- Use of existing form elements (screw-on domes, passages ...)

ML-based evaluation of the ERICHSEN deep drawing (cupping) by machine learning

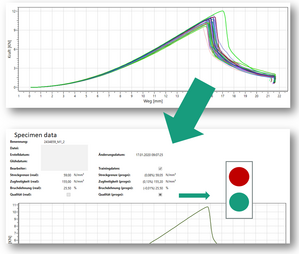

- Recording of the force-displacement curves during the cupping test

- Teaching the model in training phase:

- Instead of the maximum values of a tensile test (Rp02 / Rm / A), the test curves are used as the basis for evaluation

- At the same time, the test provides a statement on suitability (precast quality as well as derived characteristic values)

- A forecast of the target values for production:

- A "good" or "reject" assessment

- in addition, the material characteristics are shown as an estimate