Knowledge sheet metal tensile specimen preparation

Accurate results require first-class manufactured tensile samples

Why must special attention be paid to the production of tensile specimens?

Tensile test results are only as reliable as the quality of the tensile specimen allows!

- It is not a matter of punching a hole in a sheet of metal. Improper sample production leads to incorrect results that usually go unnoticed until the customer makes a complaint. If the true material properties only become apparent during further processing / customer's premises, the damage can be considerable and lead to a lasting loss of image. The reliability of the test results depends primarily on the quality of the tensile specimen. Even the best "gold-plated" tensile testing machine cannot compensate for sample-related result errors.

- Most of the processes are unsuitable for standard-compliant production. The various methods with their advantages and disadvantages are described below. It should be noted at the outset that there are actually only two or three suitable methods for producing flat tensile specimens from sheet metal in a high-quality and rational manner:

- Punching + grinding - unser Know-How since 1970 (new patent 2023: Fully automatic PSM2000-A)

- Milling, in the package roughing + finishing (Press hardened sheets are NOT millable! Milling cutters fail during the first milling)

- Laser cut, however, the melting edges must be removed by grinding / milling.

Knowledge sheet metal tensile specimen preparation

Accurate results require first-class manufactured tensile samples

Know-How for tensile specimen punches + grinding machine

... What use is a supplier who knows nothing about material testing? Many can build punching and punching tools. But who guarantees that the punching tools have a cutting gap optimised for material testing so that the material characteristics are not falsified by the sample production? The manufacturers of punching tools optimise them for low punching burrs (fine punching). However, this is NOT the essential quality feature: The damage/deformation of the punching edge results in material compaction/solidification by cold forming, the so-called "strain hardening". This increases the result for Rp0.2 and reduces the elongation extremely!

Fair advice since 1970: Rational sample preparation

With us you can expect knowledge about

- Standardised specimen dimensions with optimised punching allowance for finishing. (Negative example: A toolmaker supplied the punching tools for a nominal specimen width of b20 mm with an allowance of only 0.15 mm. As a result, the user does not test according to the standard, as the specimens would be b<19 mm after removing the work hardening).

- the minimum length for hydraulic clamps

- Cutting gap optimisation for steel, non-ferrous metals, VA steels + deep-drawing grades

- Option: Sampling lengthwise, crosswise, diagonally to the rolling direction

- Sampling >100 mm to the rolled edge

- Finishing: Worldwide unique process by

a.) Sample grinding machine PSM2000 (manual operation; new since 07-2023: Now also with active cooling during grinding)

b.) PSM2000-A (Patent pending in 2023)

Extract from ISO 6892-1 - B.4 Sample preparation

"The specimens must be manufactured in such a way that the material properties are not influenced. All areas that are work-hardened by cutting or punching during specimen manufacture must be machined down - if they influence the properties. These specimens are mainly made from sheets and strips. If possible, the rolled surfaces should not be machined.

The production of these specimens by stamping can lead to significant changes in the material properties, especially the yield/elongation limits (due to strain hardening). Materials that harden strongly should always be finished by milling, grinding, etc.

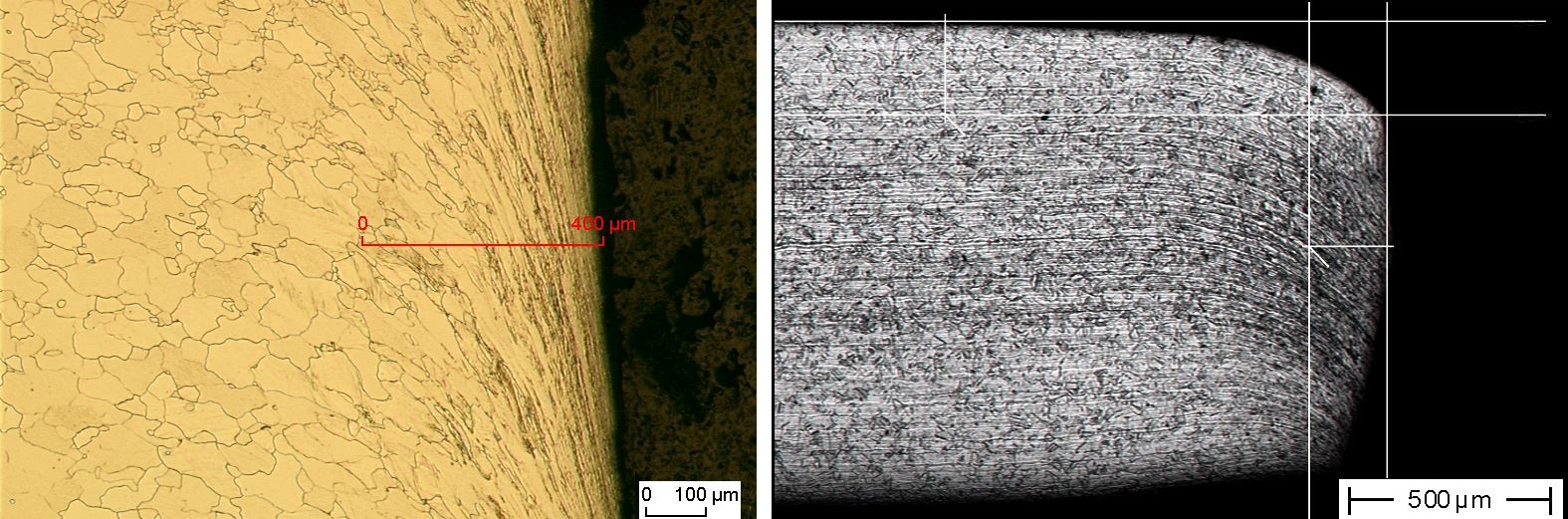

Note: Work hardening / edge deformation is even more pronounced in materials that are strongly compacted at the edges by shearing (soft grades) and in tough materials (stainless steels) that have a high toughness / elongation / deep-drawing capacity. In addition, micro-cracks occur during compaction, which imitate premature fracture (significantly lower elongation).

Do we have to grind the sheet metal specimen after blanking?

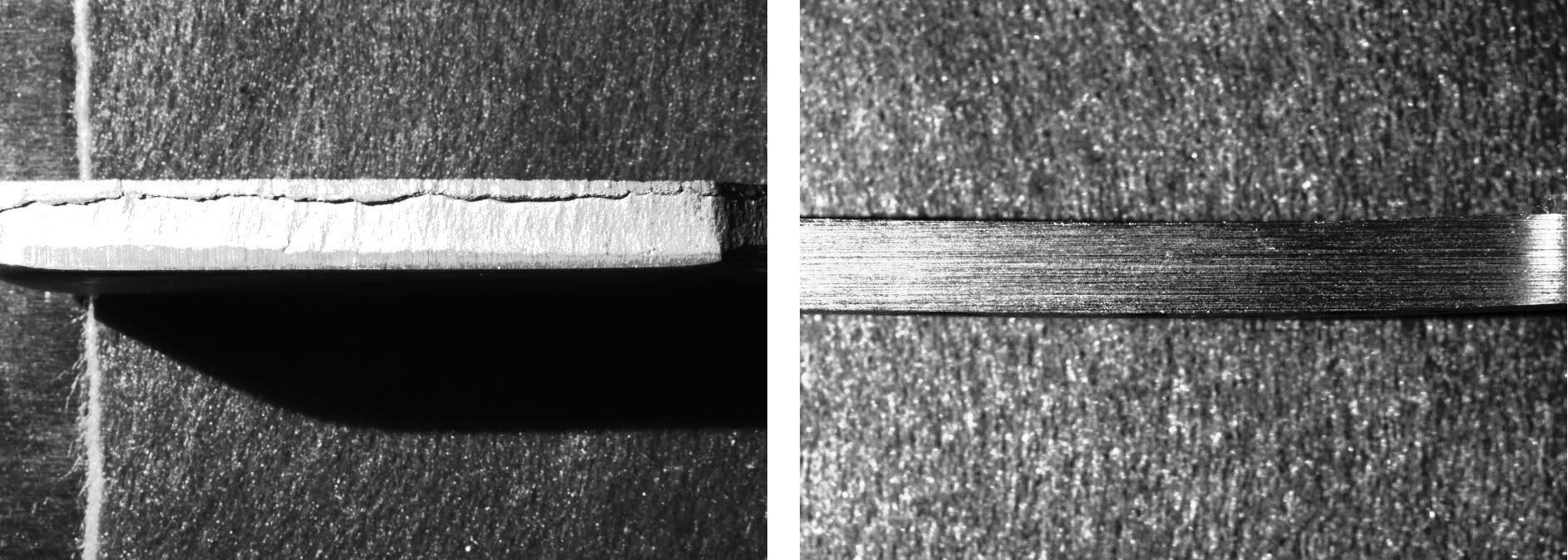

This is how we are asked by interested customers if we are to show the purpose of the PSM2000 sheet metal tensile specimen grinding machine. Without a doubt, punch edge damage (see first photo) must be removed. This is required for reliable results and ultimately this is also binding in the relevant standards. Comparing the two photos it becomes clear: With only punched sample, only a "wrong" (too low) elongation can be determined. Un-sanded samples have less elongation up to 1/3.

Important: Read why most manufacturing processes are unsuitable

- Some customers did not follow our recommendation. They cut tensile specimens with waterjet, plasma torch, wire erosion, etc., which turned out to be a mistake. - which in retrospect proves to be a big mistake.

The production of tensile specimens by punching and grinding has proven itself a million times over and is the only adequate method to produce a high-quality tensile specimen in less than 3 minutes. Our systems are used in sheet metal processing (slitting/cross-cutting lines), rolling mills, strip galvanising plants and steel service companies for the rational production of tensile specimens of unsurpassed quality.

For specimen preparation, we recommend first punching out the tensile specimen on a punching tool optimised for this task (tensile specimen production). From the (not pre-cut) metal sheet to the punched tensile specimen, this only takes about 15 seconds, including the insertion and removal of the tensile specimen and the specimen sheet. This or a stack of samples is then placed in the sample holder of the sample grinding machine and ground within approx. 120 seconds so that it can be used for testing immediately afterwards - without further processing. In a quality that is unsurpassed and "indispensable" when it comes to determining R+N values.

The undisputed advantage of the punching technique: The sheets do NOT have to be pre-cut, one can take a sample from a huge sheet.

But there are limits to the system - sheets >12 mm cannot be punched:

Typically today, tensile specimens are made from sheets <10 mm by punching. Thanks to the further development of our punches and the PSM2000 tensile specimen grinding machine, sheets up to 12 mm can now also be punched and ground. The limits are a width-thickness ratio of approx. 1.5 : 1.

By using special abrasive belts, damage to the sample due to heating above 120°C is excluded - numerous tests prove this. Measurements have been carried out several times in which a temperature of 50 - 60 °C was never exceeded. Active cooling of the grinding process is neither necessary nor sensible for tensile specimens made of steel.

New in 2023: Patented PSM2000-A or Hybrid PSM2000 tensile specimen grinder with active cooling. The situation is different for tensile specimens made of aluminium and other non-ferrous metals as well as special steels such as bake-hardening steels. For these, we developed the patented variant of the specimen grinder in 2022/2023. This cools the samples to below 45 degrees and works fully automatically. Especially against the background that it is becoming increasingly difficult to find qualified personnel, automation has become even more important in order to reduce the use of personnel to a minimum.

Punching is also useful if the specimens are to be milled rather than ground:

For milling, a rectangle must first be made with a pair of hammer shears. It is better to punch out a tensile specimen with the appropriate allowance "near net shape" and then mill it in the stack. This considerably reduces the handling effort (no need for a punching shear) and the milling time.

If you need to produce several tensile specimen forms (ISO / ASTM / JIS), it makes sense to punch a blank in "bone form" from which all the different tensile specimens can be milled - we will be happy to recommend the most favourable rough form for your requirements.

It comes to the equipment combinations:

- Punching, punching tools + sample grinding machine < 20 - 500 specimen / day)

- Punching + CNC milling >400 Samples/day or different sample forms

Eccentric presses / hydraulic punches

In the production of flat specimens from sheets up to a thickness of approx. 12 mm, punching is almost standard today. And this is where the first uncertainty arises: All national + international standards (including ISO 6892-1) prescribe the finishing of the punched edge.

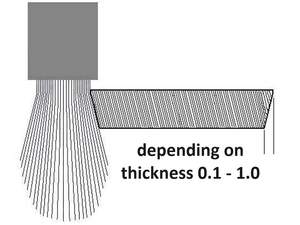

However, the standard does not say how far the strain hardening extends laterally into the material. In practice, with eccentric presses (which, due to their principle, have a high, impact-like punching speed), a strain-hardened edge zone of up to 35% per side (35% of the sheet thickness) is expected. Eccentric presses would therefore have to work with a punching allowance of 4 mm per side to remove the work hardening. This can only be achieved economically by milling.

The situation is different with slow-cutting hydraulic punches/presses. Due to the low cutting speed, the work hardening (with sheet thickness-optimized cutting gap) penetrates only up to a maximum of 10% of the sheet thickness per side. This has been confirmed by numerous microstructural investigations. For example, 12 mm thick sheets are punched with an allowance of only 1.2 mm per side in the gauge length. The specimen, which is now 22.4 mm wide, can be easily finished with the PSM2000 specimen grinder described here (recommendation: fully automatic PSM2000-A).

Specimen Punching, Punching Tools + Specimen Grinding Machine

Advantages punching + grinding technology

- Even large sheets, e.g. 1800 x 400mm, do NOT need to be pre-cut:

Saves the purchase of impact shears, avoidance of wasted labor time.

Note: For milling, a specimen must "always" be pre-cut e.g. 300 x 30mm - fastest sample production (single sample <3 minutes if the truck is waiting

- cost effective production of a high number <800 per operator / shift

(with fully automatic specimen grinding machine PSM2000-A - highest quality due to longitudinal grinding (PSM2000)

- always significantly higher elongation (compared to other methods)

- results of ReH / ReL and Rp0,2 are guaranteed to be correct

- hardly any operating costs:

Maintenance free machines: oil change 5 years / sharpening tools >20,000 - 100,000 samples - Overhaul (simple) of the grinding machine every 10 years

- Can be automated (robotic system: from sheet metal to punched, labeled tensile specimen

- NO skilled personnel required to operate the system, even semi-skilled workers can produce 1A tensile specimens

Disadvantage punching + grinding

- uneconomical with few samples per day / week --> have samples milled

- Automation costly

CNC controlled milling machine

bei <20 Proben/Woche ist fräsen (durch ein Unternehmen in der Nachbarschaft) die bessere Wahl

Advantage CNC milling

- Flexible use also for different specimen shapes

- Use of this machine tool also for other tasks

- in case of a high volume of specimens, the "unmanned" automatic processing (specimen stack) "pays off

Disadvantage CNC milling

- ajor disadvantage: sheets must be pre-cut to approx. (approx. 300 x 40 mm) (time-consuming, impact shears required).

z. e. g. a sheet metal plate of approx. 1800 x 400 mm cannot be milled. - Can cause high investment costs

- Long production times (logistics and waiting times for urgent tests)

- Operating and maintenance costs

- Wear of the milling cutter...

- The operation of the equipment requires skilled personnel, which is difficult to find nowadays.

Conventional milling with manual control

Handsteuerung ist personalaufwendig und ist nur so reproduzierbar wie die Bediener-Fähigkeiten

Advantage conventional milling

- Low investment costs, among other things, used equipment can be purchased.

Disadvantage conventional milling

- Major disadvantage: sheets must be pre-cut to approx. (approx. 300 x 40 mm) (time-consuming, impact shears required).

z. e. g. a sheet metal plate of approx. 1800 x 400 mm cannot be milled - The advantage of the inexpensive purchase is quickly eaten up by the personnel costs.

- Long manufacturing time (waiting time for urgent tests)

- Precise samples can only be produced with increased effort

- There are operating and maintenance costs, wear of the cutters, etc.

- The operation of the plant requires skilled personnel, which is difficult to find today.

Wire erosion of tensile specimens

ungeeignet sofern die bearbeitete Kante nicht nachbearbeitet wird

Advantage wire EDM

- Extremely hard sheets can also be cut

- Wire EDM machines operate fully automatically after loading

- Stacks of samples can be processed

Disadvantage wire EDM

- Very high acquisition costs

- Extremely long processing time (waiting time for urgent samples)

- Edge roughness does not meet the standard

- Extremely expensive consumables - cutting wire quickly costs >10,000 / 50,000 € and more per year

- The operation of the equipment requires skilled personnel, which is difficult to find nowadays.

High-pressure waterjet cutting

Water jet cutting is unsuitable for tensile specimen production: slow, expensive, rough flank, expensive service

Advantages waterjet cutting

- Very universal, cuts all materials

- Processing of all sheets, including high-strength, difficult-to-punch sheets (strength > 1,600 MPa)

- Machining of sheets over 12 mm thick

Disadvantages waterjet cutting

- Partially extremely long processing times (waiting times for urgent examinations).

Customer experience (acquisition errors): Only approx. 4 (four!) samples / day can be produced in order to obtain a standard-compliant Flankengüte zu erzielen! - Qualified personnel is required for the operation of the equipment.

(which is hard to find in this day and age). - High operating and maintenance costs are incurred

- In addition to the water, abrasive granulate is required - complex, cost-intensive disposal of the sludge

- The specimens are rusted (if no anti-rust emulsion is used) already the next day

- Separation is transverse to the tensile direction - the surface roughness of the cut surface must be improved by finishing (grinding) for roughness <6.3µ Rz

- your purchase as more than 3 axes of motion are required (inclination of the cutting beam to avoid conicity of the sample

- Different programs must be created / selected for different sheet thicknesses so that the conicity compensation does not lead to undefined specimen widths (specimen width e.g. b = 20mm

Laser cutting of tensile specimens

suitable if the edges are reworked by grinding / milling, very well suited for hard sheets, very flexible specimen shapes possible

In steel/sheet mills where specimens other than tensile specimens must be produced, a system for laser cutting of sheets is probably the most useful (multi-stage) method of production.

Frequently required specimen shapes

- Tensile specimens according to ISO 6892 (20 x 80)

- Tensile specimens other specimen shapes acc. to ISO 6892 (12.5 x 50), JIS, ASTM, GOST

- Circular blanks for zinc coating thickness measurements

- Squares for roughness measurements

- Rectangular specimens for bending stiffness measurements

- Plates as retain samples

- Note: Tensile specimens must be finished by milling or grinding!

Advantages laser cutting

- universal, cuts all metale

- Machining of hard sheets with high strength > 1,600 MPa possible

- Machining of sheets over 12 mm thick

- In the automotive industry, a laser cutting system is often already available for trimming pressed parts.

Disadvantages laser cutting

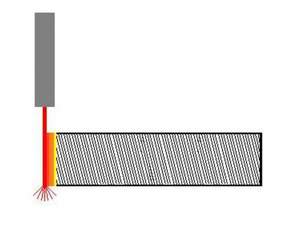

- For the production of tensile specimens only suitable for sheets < 6.0 mm (the heat-affected zone is limited to a depth of approx. 0.6 mm and can be easily removed with the specimen grinder PSM 2000 - the combination of laser cutting and specimen grinder is very often used. Press hardening in particular: Anyone who has ever tried to mill magan steel will "despair" of it - the toughness will destroy any milling cutter. This leaves only laser cutting and grinding.

- Very high investment costs

- The operation of the equipment requires qualified persons

- High operating and maintenance costs

- In any case, the specimen must be reworked after fabrication, since thermal processing with the laser creates a thermally damaged heat zone that strongly distorts the results (double processing).

- The operation of the equipment requires specialized personnel, which is difficult to find nowadays.

Plasma cutting of tensile specimens

Extremely unsuitable because the enormous heat input changes the microstructure, the edges have to be reworked in an extremely time-consuming manner

Extreme heat is generated during plasma cutting of sheet metal. The specimen even becomes incandescent at the edges, and the heat input extends laterally very deep into the material. The heat input causes extreme changes in the material properties. All areas heated above 120 degrees must be removed by milling or grinding. This type of sheet metal processing is extremely uneconomical, as an extreme amount of reworking is required.

Advantages plasma cutting

- universal, cuts all metals

- Machining of hard sheets with high strength > 1,800 MPa possible

- Machining of sheets over 12 mm thick

Disadvantages plasma cutting

- High investment costs (if only for sample preparation has to be purchased)

- The edge roughness (unmachined) is far from the required roughness 6.3 Rz!

- High operating and maintenance costs are incurred

- In any case, the specimen must be reworked after fabrication, since processing with the plasma torch creates a thermally damaged heat zone that extremely distorts the results (double processing).

- The operation of the equipment requires skilled personnel, which is difficult to find nowadays.

Nibbling machine for the production of tensile specimens

completely unsuitable because the sheets flutter, the edges always have to be reworked

In our view, a nibbling machine is the worst and completely unsuitable method for producing tensile specimens. The nibbling / punching edge must be heavily reworked, since (as with punching) cold forming (strain hardening) occurs. Without post-processing, the results ReH / Rp0.2 are strongly distorted (exaggerated) and the elongation at break is strongly reduced. The edge cut only by nibbling is in no case in conformity with the standard. In addition, the cut edge is usually not linear and requires reworking (grinding or milling) in any case.

Advantage nibbling machine

- High working speed

(which, however, produces a 3-fold larger work hardening zone due to the high punching speed - see eccentric punching).

Disadvantage nibbling machine

- High investment costs

- The edges must be finished in the same way as for punching

- Fluttering of the sheet occurs (depending on the constantly changing sheet thicknesses) (unsuitable for different sheet thicknesses)

- Für die Bedienung der Anlage ist Fachpersonal erforderlich, das heutzutage schwer zu finden ist.