drop weight marking system with digital scale for round tensile specimen

lower drop heights for sensitive samples (alu, copper...

Interested? Watch the short video

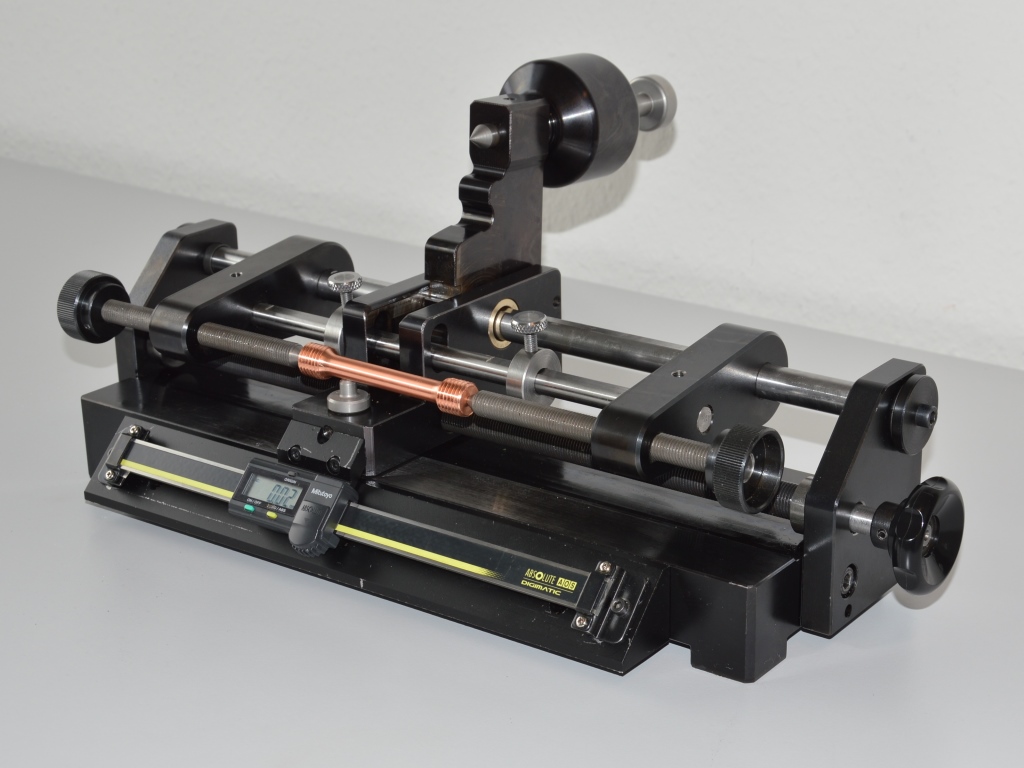

Unit different to above - with digital scale

Rational marking of turned tensile specimens for manual measurement of elongation at break

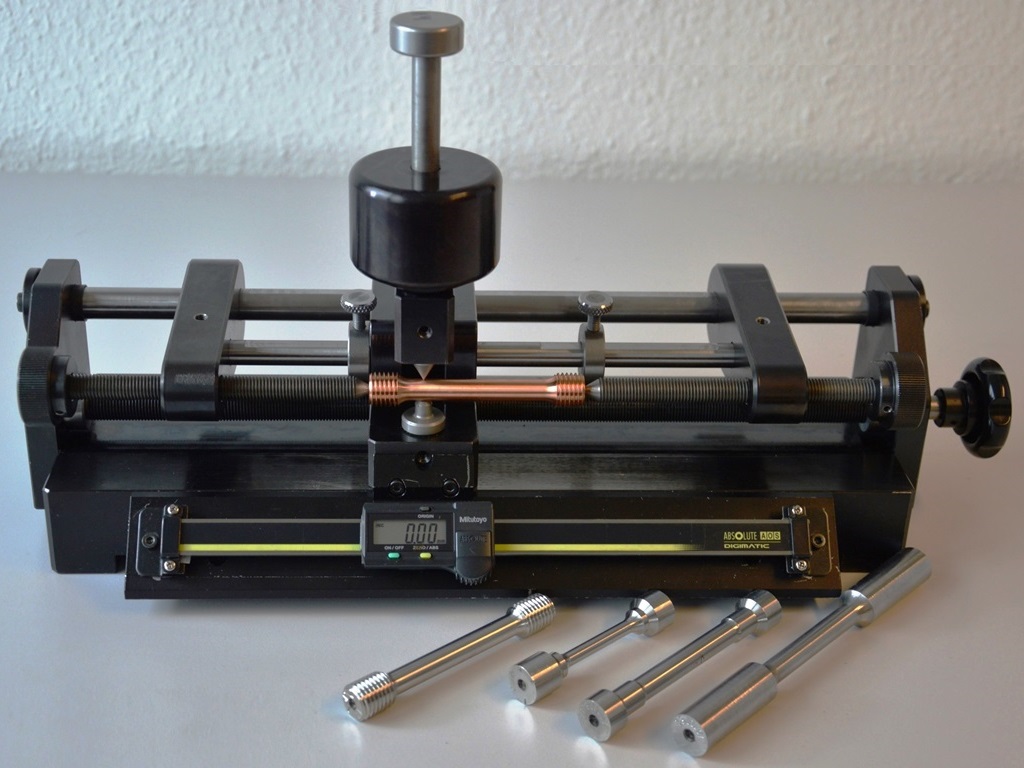

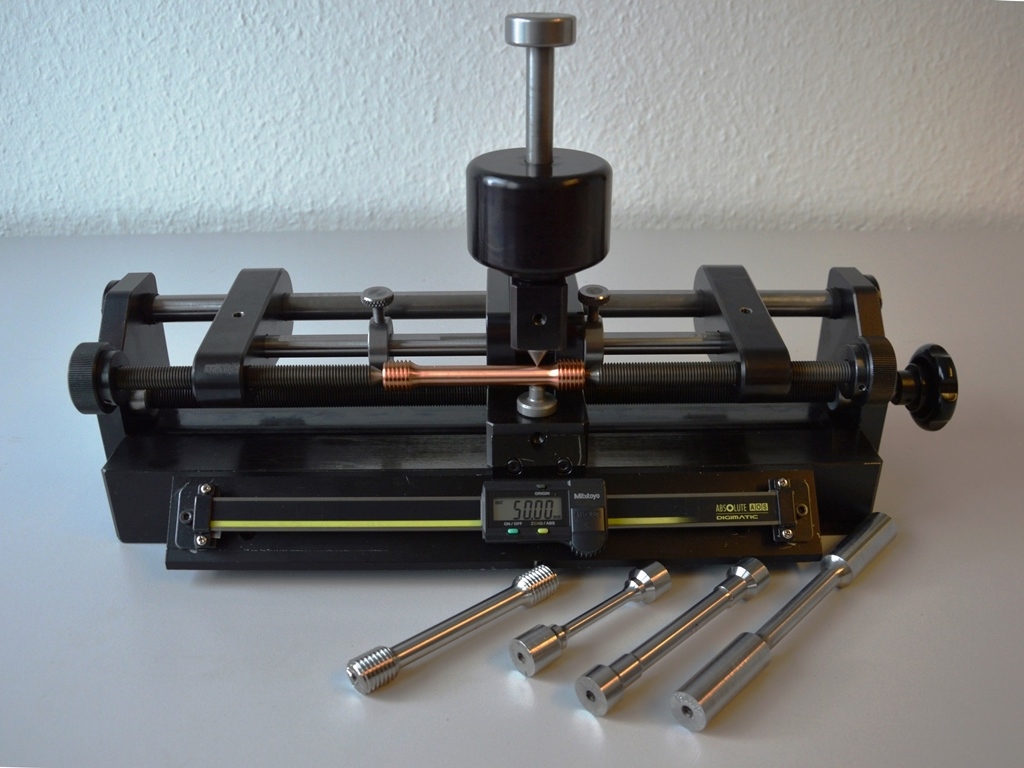

With this device thread / shoulder / cylinder head tensile specimens can be rationally marked with centre punch points by means of a drop weight. This is used for the manual measurement of the elongation at break in the tensile test in accordance with ISO 6892 / ASTM E8 / JIS and other. This type of manual measurement of the elongation after break conforms to the standard and is (if the marking of the specimens can be carried out rationally) insignificantly more time-consuming than the use of a (cost-intensive) automatic extensometer.

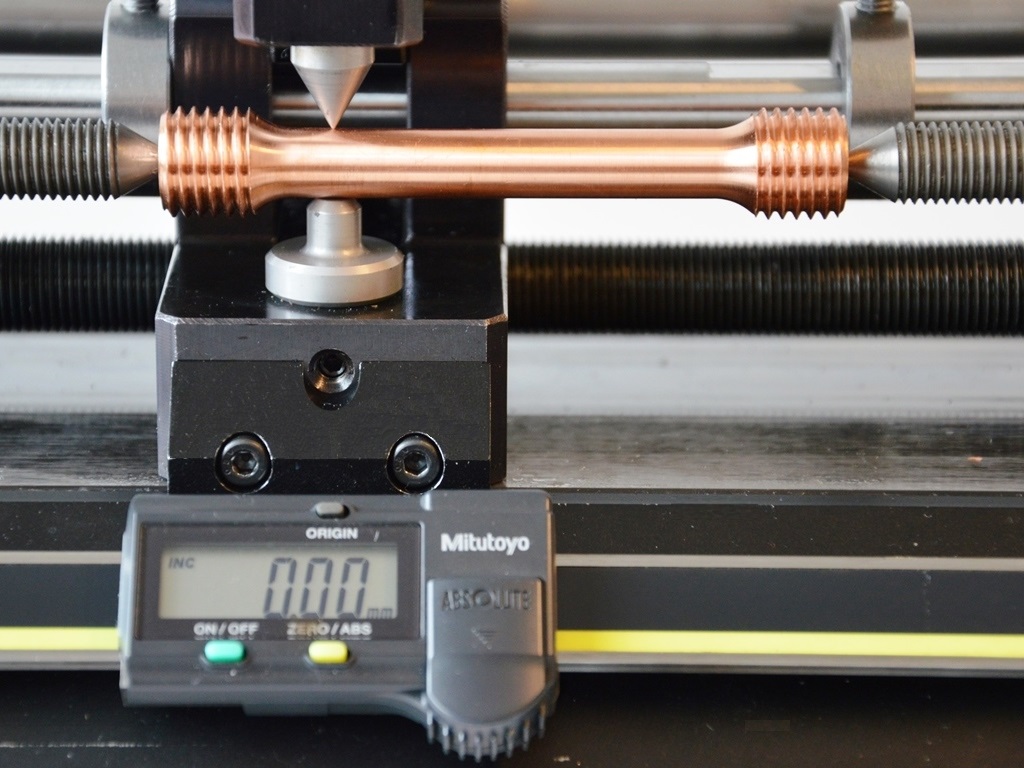

The markings must be applied and measured with an accuracy of +1% (e.g. L0 50 mm +0.5mm). Using the horizontal digital scale integrated into this fixture, position stops can be set very accurately. Once this is done, a sample is clamped between the centres. If a centre countersink is only available on one head of the specimen, sleeves with internal threads (threaded head specimen) or clamping sleeves are available. After clamping, the drop weight is lifted and the first centre punch point is set. Now the drop weight device together with the anvil is moved to the second stop. Here the second marking is made. After removal of the double-grained sample, the next marking starts from this point B. If multiple marking of a single sample with offset is required, e.g. 5 mm spacer discs (discs with U-opening) are available which can be inserted in front of the stops.

Elongation at break measurement

To determine the elongation at break, the broken sample is placed in a prism (special accessory) so that the axes of the two broken pieces form a straight line. Then the extension (Lu) is measured with the tips of a digital caliper. The measured value can be transferred to the open field of the testing software (input Lu) by pressing a key (USB-converter required).

- If a low sample volume does not allow the purchase of a cost-intensive extensometer, this method can be used to test in compliance with standards

- For critical applications, it is also sometimes necessary to measure the elongation at break using conventional methods

- Furthermore, manual measurement of elongation at break according to various applications for aircraft / space industry is mandatory (ASTM / NADCAP / BS / API).

The marking device is (manufactured in Germany) can be operated efficiently and applies the desired sample marking within seconds:

- Clamp turned specimens

- Move anvil and centre punch to the stop

- Lifting and dropping the drop weight

- Move anvil to 2 position

- Repeat the beating process - done

This marking device is suitable for the following turned round samples with:

- smooth cylinder heads

- Thread heads

- shouldered heads

- with conical heads